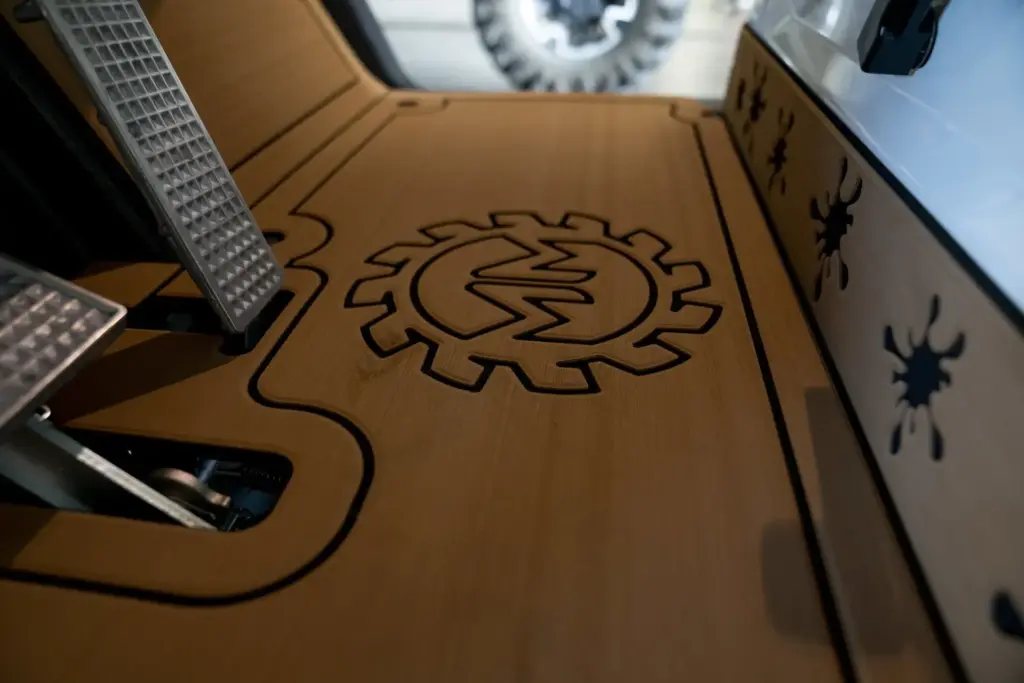

Personalize Your Deck With Precision-Cut Logos, Boat Names, and Graphic Designs

Make Your Boat Truly Yours

Nothing elevates a boat’s appearance quite like a custom logo or inlay integrated directly into the decking. DeckLab™ specializes in designing and fabricating multi-layer, precision-cut inlays that transform your deck into a personalized showpiece — durable, stylish, and engineered to last.

Whether you want your boat name, company branding, tournament team graphics, or a unique design element, our CNC engraving and inlay process delivers incredible detail and a flawless, professional finish.

Why Choose Custom Inlays?

Personalized Style

Give your boat a unique look that sets it apart from every other vessel at the marina.

High-Detail Precision

We use advanced CNC equipment to cut fine details, crisp text, and complex shapes with accuracy.

Durable Multi-Layer Construction

Two-tone or three-tone laminated foam creates high contrast and visual depth.

Permanent, Professional Finish

Your inlay becomes part of the deck — not a sticker, decal, or surface print.

Branding & Identity Options

Perfect for charter boats, tournament teams, marinas, captains, and businesses.

Types of Custom Inlays We Create

Whether you’re outfitting a fleet or adding value to your sales inventory, DeckLab™ offers professional, reliable fabrication at scale.

Request OEM/Dealer InfoBenefits of Working With DeckLab™ Fabrication

Marine Engineering Expertise

Our team understands how boats are built — not just how to cut foam. That means better design decisions and cleaner fitment.

Repeatable Precision

Once templated, your design can be reproduced flawlessly anytime, perfect for fleets or future replacements.

Superior Material Quality

We use high-density, UV-resistant, closed-cell EVA foam engineered specifically for marine environments.

Quality Control at Every Step

Each piece is checked for alignment, depth accuracy, and overall finish before it leaves our shop.

Design Collaboration

Our designers work directly with you to create layouts that match your boat’s style, branding, and functional needs.

How We Build Your Custom Inlay

Design Consultation

Share your ideas, artwork, or logo. We’ll discuss colors, placement, sizing, and layout.

01

Vector Graphic Engineering

Our designers convert your artwork into precise CAD files for CNC cutting.

02

Multi-layer lamination

We prepare two-tone or three-tone decking sheets for contrast and depth.

03

CNC Fabrication

Your design is cut with perfect accuracy to reveal the layers beneath.

04

Installation or shipping

Choose professional installation or have your inlay shipped as part of a larger flooring kit.

05

Ideal Locations for Inlays

Custom inlays look incredible in high-visibility areas such as:

Helm pads

Cockpit floors

Swim platforms

Casting decks

Entry steps

Dealers upgrading inventory

Bow seating areas

Cooler and hatch tops

Transom steps

Jet boat platforms

If you want it to stand out, we can place it there.

Frequently Asked Questions

Can you match my boat’s graphics or upholstery?

Yes — we can match colors, styling, and themes for a cohesive look.

What file types do you accept?

We accept high-resolution artwork in AI, EPS, SVG, PDF, PNG, or JPEG.

Can I see a digital preview before cutting?

Absolutely. We always provide a design proof for approval.

How big can the inlay be?

As large as needed — from small accents to full-deck centerpiece graphics.

Will the inlay wear out faster than the deck?

No. It uses the same marine-grade materials and adhesive backing for consistent durability.

Ready to Get Started?

If your boat is in our template library, you’ll enjoy one of the fastest and most cost-effective ways to upgrade your deck.